You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anti roll bar

- Thread starter Hopelessness

- Start date

I've got a feeling this might be entirely possible!

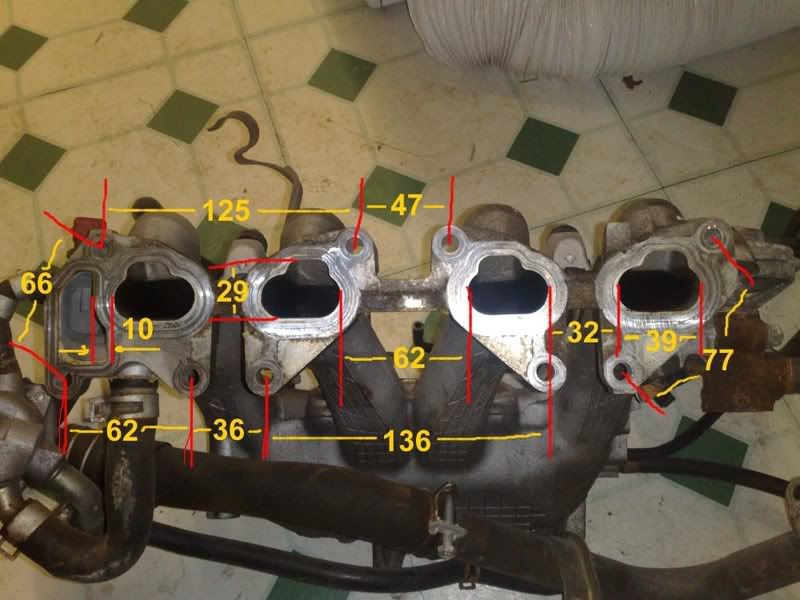

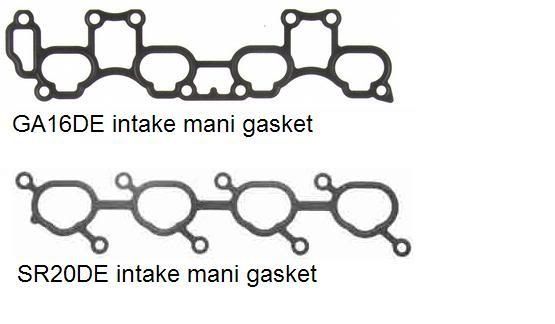

Just looking at pics of intake mani gaskets, now I'm not sure on scale, but there's the ports might line up...

Just looking at pics of intake mani gaskets, now I'm not sure on scale, but there's the ports might line up...

What would be the problem with those parts?

lol Good start... thanks  Still a rough idea of port spacing mind. If the ports are spaced in such a similar place, surely it would be possible to weld a GA compatible port plate onto the SR intake mani, thus losing the problem of conflicting bolts...

Still a rough idea of port spacing mind. If the ports are spaced in such a similar place, surely it would be possible to weld a GA compatible port plate onto the SR intake mani, thus losing the problem of conflicting bolts...

It's what's available really, cheap derestriction here really.

Btw Dale, did you get JWT cams? If so, how much, how easy to fit, how suitable to N/A are they?

Btw Dale, did you get JWT cams? If so, how much, how easy to fit, how suitable to N/A are they?

It's what's available really, cheap derestriction here really.

True but it's not gonna do much good if all that lovely new large amounts of air has nowhere to go...

Without a full exhaust system i can't see this being very beneficial.

Well I'll have a full exhaust soon... plus sooner rather than later I'm gonna get some headwork done...

Why not an alu adapter?

Why not an alu adapter?

True but it's not gonna do much good if all that lovely new large amounts of air has nowhere to go...

Without a full exhaust system i can't see this being very beneficial.

This is true, like i said in an earlier post, what about doing the same with the exhaust? GTi manifold and downpipe (cheap, i will have a manifold going begging very soon) and GTi (or stainless) system.

I'm getting a GTi cat back in a couple of weeks, I'm gonna get an OBX manifold when the exchange rate picks up a bit.

Well I'll have a full exhaust soon... plus sooner rather than later I'm gonna get some headwork done...

Why not an alu adapter?

Yeah suppose you could use an Aluminium adapter but then there is the cost of getting it welded (as you probably know Ally welding is tricky (heating up the parts to be welded etc) thus expensive and i am thinking that when we have developed the adapter and start SELLING them i don't think it would be viable for some of the prospective customers to have this sort of welding done.

Patent?

I think this little idea has some serious legs.

I'm getting a GTi cat back in a couple of weeks, I'm gonna get an OBX manifold when the exchange rate picks up a bit.

That sorts the exhaust then.

Excellent work CoV, anyone wanna shed some light on the SR20 spacing?