have you got cam gears? as this is one of the reassons i think they do the whole -5 +5 thing with the N1 cams on 2.0 motors..

yeh thats what i'm saying about doin above - is it -5 intake, and +5 exhaust you're talking about ian? thats what i have in mind to widen the lsa

I know I gave Jez a big up to you but 4* ignition timing is fucked...unless you're a tooth out?

no they checked the cam timing, but alas i had it spot on. tbf to jez it's not really his fault it was oulled back that much to stop the nasty detonation. i'm just waiting on a reply from him to see if it was the base timing or mao he altered

Are you using adjustable cam gears? If so which ones are you using? I'm trying to decide which ones to get, the purple ones on gspec or bc ones on ebay.

i got the jwt ones mate, but wish i'd seen those slider type mentioned in your thread with the arp clamping bolts. much easier to tune

Well i'd go down the line of sorting the N1 cam switch points, get your MSS switching the cams independantly of each other first.

Sort the oil burning out too...

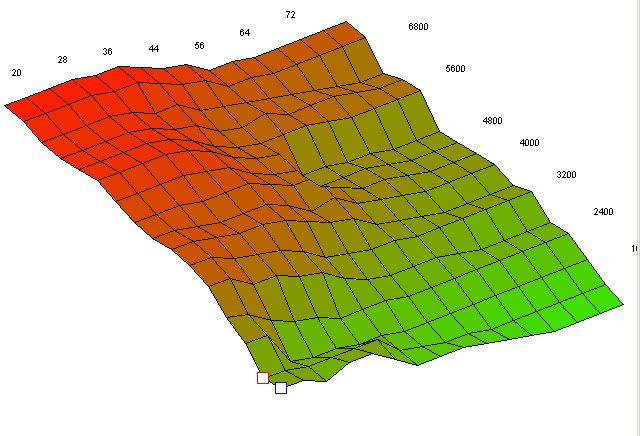

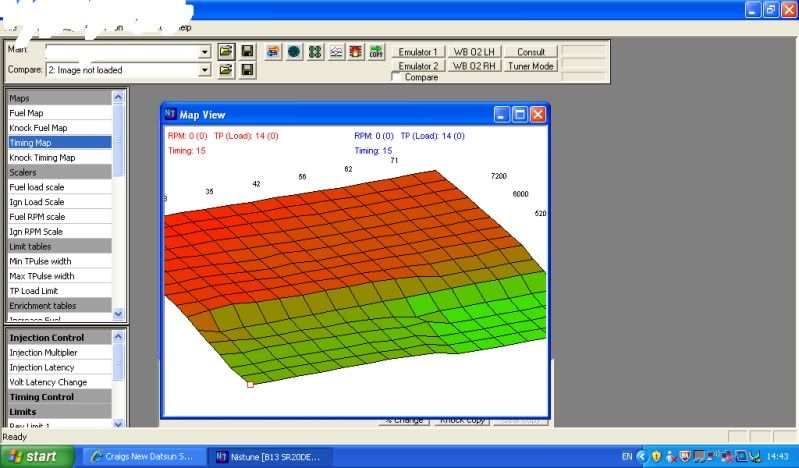

....THEN get yourself another mapping and dyno session and get the igntion timing optimised, and then look at cam timing if you still arent seeing the results you expect. I think sorting the switch points out so that they engage independantly will make a good difference to the power delivery too. From what ive seen, a 600rpm gap seems like a good setup. Perhaps 5300/5900rpm with N1 Cams.

Im not going to encourage that you mess with your LSA and base ignition timing yourself, its needs doing by a tuner on a dyno with headphones to listen for pinking and make to the necessary adjustments to the fuel and timing maps. (.... and I dont want any responsibility if you fuck it up) :lol:

I think it just needs some more tuning time... as you said yourself, you ran out of time for a dyno session due to problems and you had to have it road mapped intsead.

hmmm, don't think i can sort the independent switchin without a new mss - one channel is permanently on lol and my money's tight.

also, i'm wondering if using 99 ron fuel with decent booster will be enough to stop any pinking and allow the timing to be upped. reason ithought about widening the lsa before a mapping seshwas A) to lower the effective comp and B) because Jez didn't seem too keen on cam gear tuning etc unfortunately

i'm also gonna make some det headphones for if i messs with owt lol