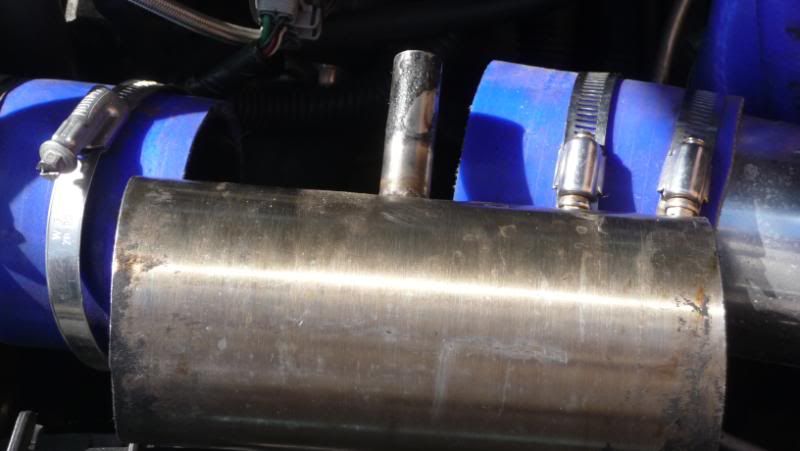

Car is booked in for remap on Tuesday after the exhaust has been finished so hopefully some new power figures and pictures coming soon.

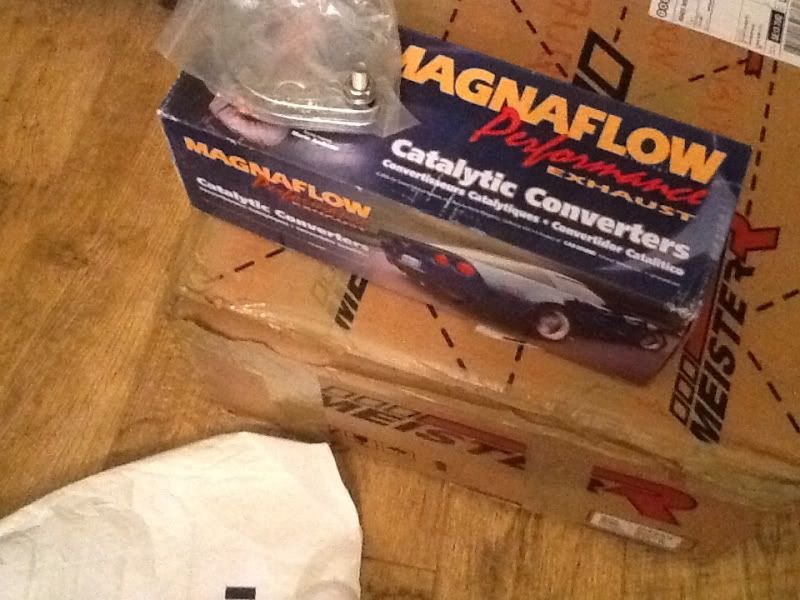

Also a few more things arrived today to add to the pile of items on the to do list:

New licence plates with a personal twist to them and large quantities on epoxy resin chassis paint ready for undersealing the underneath of the car.

I'm still awaiting my car ramps to arrive so I can press on with the protection work, I'll try to get images if I've managed to avoid covering myself in more paint the the car...

Also a few more things arrived today to add to the pile of items on the to do list:

New licence plates with a personal twist to them and large quantities on epoxy resin chassis paint ready for undersealing the underneath of the car.

I'm still awaiting my car ramps to arrive so I can press on with the protection work, I'll try to get images if I've managed to avoid covering myself in more paint the the car...