last night took some measurments with a digital vernier.

DET

dowel holes in head - 15.1mm

head bolt holes in head - 13mm

head bolts - 11.9mm (under the head of the bolt were its slightly wider)

head bolts - 10.8mm (around thread)

VE

dowel holes - 13.6mm

head bolt holes - 12mm

head bolts - 10.9mm (under the head of the bolt were its slightly wider)

head bolts - 10mm (around thread)

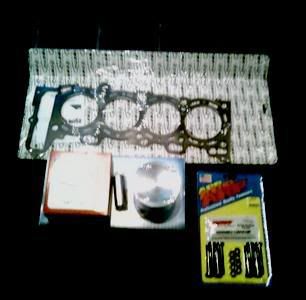

basically we are going to machine the VE head to the same measurements as the DET head. 1mm out of the head bolt holes and 1.5mm out of the dowel holes.

the VE finally meets DET

i placed the head on the block and the dowel holes are tapered slightly so the head slotted on but wouldnt go right on as obviously the holes arent big enough, its was very good to look down the head bolt holes and everything lined up perfectly

to my suprise the DET head bolts actually fit in the VE head but they are very snug, tiny bit of play around the thread but when the wider bit of the bolt met it, it was tight but still went all the way in. nissan made it with a bit of play so we are going to keep it that way