Was the front bumper in a good condition and is it available for sale ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stani's SR20 Micra Build

- Thread starter stani1029

- Start date

Was the front bumper in a good condition and is it available for sale ?

Couldnt really tell as it was dirty mate, i remember seeing a scuff on one corner and its currently under all the rubbish in the car lol.....

it will be a little beast! like it...

The micra build not the floor mate...worring about the fucking floor being common.Cheers and ill take credit if she fires up and all electrics work at first time of trying! Will know in a few months i suppose

Regarding the flooring its pretty common, im in alot of houses so come across it a fair bit lol

Rear arches are now patched, then zinc primered over both sides

Made a start on weld filling the holes where dave had drilled out the rear mounts but no photos as it aint finished.

Plan is to have the interior welding/grinding done then move onto getting the engine mounted and measured up and order drivehafts

Made a start on weld filling the holes where dave had drilled out the rear mounts but no photos as it aint finished.

Plan is to have the interior welding/grinding done then move onto getting the engine mounted and measured up and order drivehafts

what was used to cut that out?

I hope you didnt think i cut that LOL it was whoever owned the car before dave, i squared it off and the new patch was 5mm bigger either way and welded both sides

Do your corners first, then it gives you a start and a finish x x

Ah i will from now on

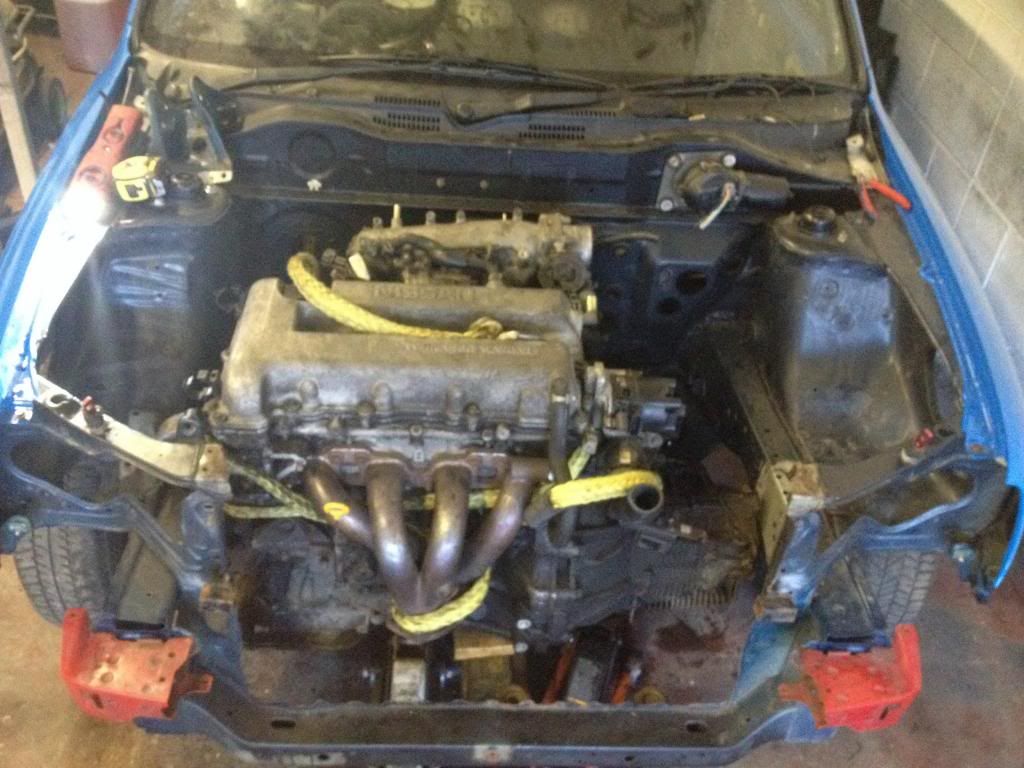

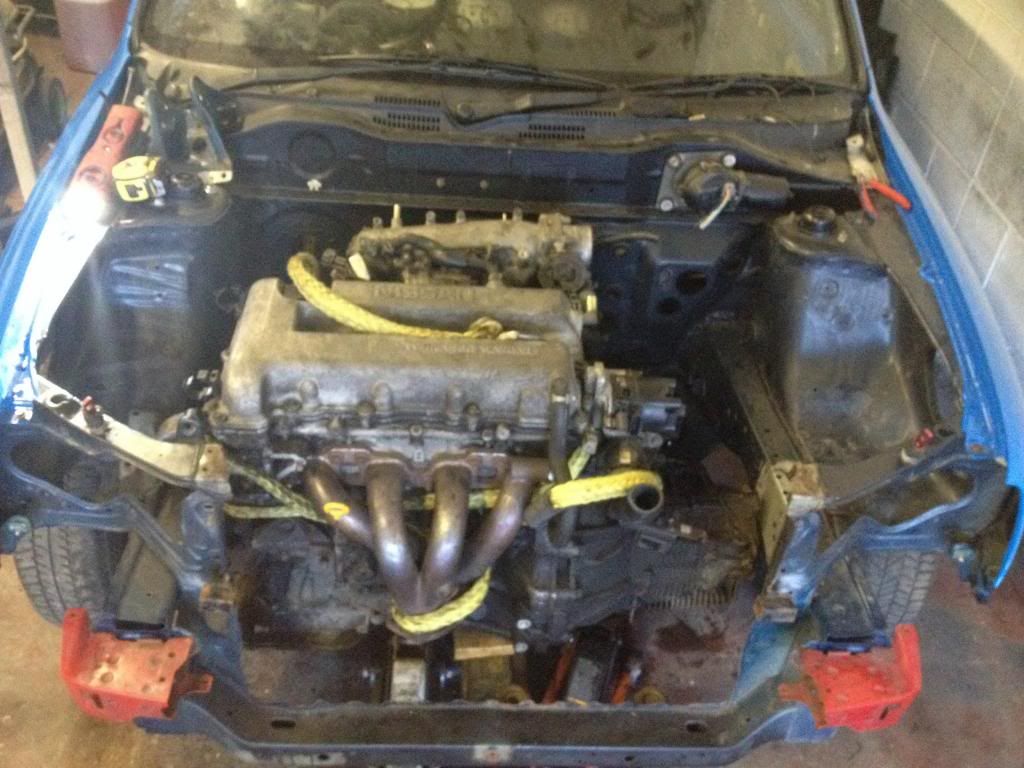

Had another few hours at it today, decided to do something a bit more fun and make a start on the engine. Borrowed my mate glen's centre member from the sr micra me and him pieced together so it gave me a good starting point for the other 2 mounts!

Going away back up tonight to mess about with it, the LH and RH mounts are marked up ready to weld so might get that done but i think i should make my centre member first incase it doesnt quite match this one...

Going away back up tonight to mess about with it, the LH and RH mounts are marked up ready to weld so might get that done but i think i should make my centre member first incase it doesnt quite match this one...

I did end up back at the car tonight and everything went spot on. Heres what we do to the centre member to take the rear engine mount. It lands exactly in the middle of that (no idea how others have done it but it works for us)

Also got the LH mount tacked on and engine is back in

Next time up ill be looking to have the RH mount completed the finish of the rear

Also got the LH mount tacked on and engine is back in

Next time up ill be looking to have the RH mount completed the finish of the rear

Great progress buddy. With your welding you want to go forward a bit and then pause and knit that pool with the cooling pool you've left before. When you get in a rhythm it's easy and you'll end up with a stronger weld and better penetration. Latin down straight beads is easy, the hard bit is sticking the two bits together like they were made in one piece.

Great progress buddy. With your welding you want to go forward a bit and then pause and knit that pool with the cooling pool you've left before. When you get in a rhythm it's easy and you'll end up with a stronger weld and better penetration. Latin down straight beads is easy, the hard bit is sticking the two bits together like they were made in one piece.

Yeah you can see where ive start and stopped eh, so your saying to hold the weld longer where ive just stopped and that will bring the joins together better? I could have done the whole lot in one swoop but i was worried about messing that up lol

I got a tad welding happy and done along the underside too but better beefing it up now than it failing on the car