You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Biscuit Build

- Thread starter white_biscuit

- Start date

What so much more is there to it..

What so much more is there to it..

Everything has to work together.

Why are apple computers so much more efficient than a comparable pc?

Because each component was designed to work with the others.

Do you know what oversize valves you will use? Do you know if you need them? Do you know what stem size you need? Do you know if they even exist?

You really cannot just buy every part based on how pretty it looks, its brand whoring capabilities or its jdm credentials and hope they all fit together just dandy. Its a higher level of thought required. Higher than you are capable of tbh (or me. Or most people on this forum)

Im not purely buying things coz they look shiny or big

Yes i am working out what i think i need, and im not saying I've automatically become a race engine builder, but im trying to build an engine

Well, atleast im trying eh!

Yes i am working out what i think i need, and im not saying I've automatically become a race engine builder, but im trying to build an engine

Well, atleast im trying eh!

Dave bull shall be along soon to condemn the use of thicker head gaskets to change compression

especially on a 92mm gasket which isn't the easiest thing to seal anyway...has to be perfect by sound of it

cory's having trouble with his atm he thinks, he's also struggling to make much more power from using a stroker crank on his 2.4 build.

he's like 20-30hp off where he was aiming and is now wondering if the cams work well with the crank, if the octopus header thats mahoosiv isn't working well,

all that and he's got 2 epic build alread to his name, a miko worked ve head so he knows its worked properly and very well, and a wealth of knowledge.

ammars not got a cam thats designed or proven for a stroker, not got a clue what header could/couldnt work well until it's tried out, very trial and error. I suspect doesn't have someone who knows the sr20de head well enough to work it to perfection for maximum gains. Plus to get to where he is now Corys had a couple of headers and intakes trial and error, and it still isn't working well on the 2.4 it seems

THIS^ is the kind of thing i mean Ammar...i'll happily eat my words if you bolt it all together first off and make mahoosiv figures, but imo it'll need a lot more trial and error to get there....thats all i was trying to highlight. And the only reason i'm trying to highlight it is cos i don't believe that you'll just be happy it works and runs.....anyone going to the time and expense of building a 2.4 wants some serious power....else whats the point?!

Thats what i've been telling you for weeks about there being more to it to get the most out of it...just the way you talk sometimes it's like its gonna be easy bolt on and go with uber powerz and i'd be highly surprised if it was.

thats all

Ah dude cant you just buy POCs vvl head, put it on a 88 x 86 setup with craigs pistons then have lots of fun with that!?

This guys title thread says vvl assassin, so no vvl parts allowed.

Seriously though ammar just start ve.

Seriously though ammar just start ve.

Ah dude cant you just buy POCs vvl head, put it on a 88 x 86 setup with craigs pistons then have lots of fun with that!?

now there's a man with a plan :wink: that'd make 210whp all day long, maybe 220 with custom intake and header

shaggy_master

brapp brapp!

Let's face it none of us are gonna go anywhere fast with no proper Diffs

Especially with the Quaife one going balls up

You pulled yourself out Joe/?

You pulled yourself out Joe/?

shaggy_master

brapp brapp!

Yeah man unless they go back to their original quote.

£620 is nismo territory tbh

And with my engine to finish, and Zante with the lads in 2 weeks, fuck that man

£620 is nismo territory tbh

And with my engine to finish, and Zante with the lads in 2 weeks, fuck that man

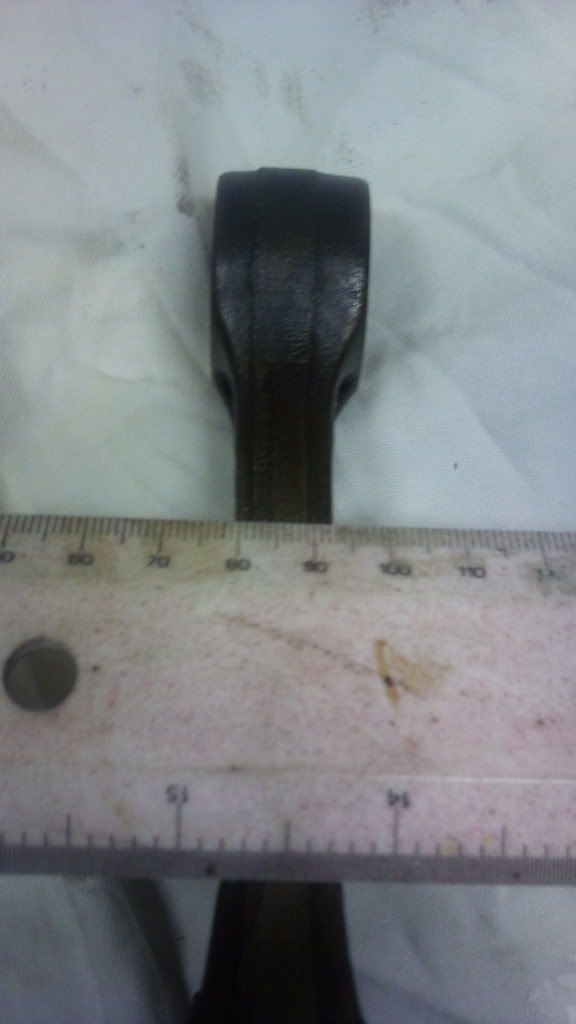

Post also handy for this thread if you can measure DE rods too (I take it that above is a VE rod? Some text might be handy  ) - http://www.almeraownersclub.com/threads/34807-SR-Factory-RODS?highlight=compare+stock+rods

) - http://www.almeraownersclub.com/threads/34807-SR-Factory-RODS?highlight=compare+stock+rods

No that above looks the same width to me as a GTi-R Rod

I think the way it goes is,

VE - 10mm

DE - 12.5mm

DET - 15mm

Also, these rods are the lightest ones i've seen around

Eagle Rods - 525g

Manley - 574g

K1's - 524g

Carlillo - 525g

These @ 472g

So with a heavier crank, but REALLY light pulley's, fly and pistons should be ayt..

I think the way it goes is,

VE - 10mm

DE - 12.5mm

DET - 15mm

Also, these rods are the lightest ones i've seen around

Eagle Rods - 525g

Manley - 574g

K1's - 524g

Carlillo - 525g

These @ 472g

So with a heavier crank, but REALLY light pulley's, fly and pistons should be ayt..

shaggy_master

brapp brapp!

You don't measure the thickness there you fool...

Lol

Lol

You don't measure the thickness there you fool...

Lol

So where do you measure the thickness of the rods?

shaggy_master

brapp brapp!

On the part that's machined flat at the big end bearing end.

The rods are tapered in the middle so you could get any measurement tbh.

The thickness is only important so you get the correct big end bearings anyway... GTiR or non GTiR so it makes sense to measure the thickness across the bearing surface.

The diagram you just quoted from raceworx is only good to establish the difference in shaft thickness.

Joe

The rods are tapered in the middle so you could get any measurement tbh.

The thickness is only important so you get the correct big end bearings anyway... GTiR or non GTiR so it makes sense to measure the thickness across the bearing surface.

The diagram you just quoted from raceworx is only good to establish the difference in shaft thickness.

Joe

Yeah as i said, not measuring bearing sizes at the moment.

This was just to confirm the differences in the rods for SR!

I hadn't seen Raceworx thread prior to this..

This was just to confirm the differences in the rods for SR!

I hadn't seen Raceworx thread prior to this..